Features of JH series:

》Modularization structure design,can upgrade machine function according to customer's requirements.

》Humanized design attachment installation easy and fast to operate.

》Special equipped with paper regulation device.

》Special first folding line,third folding line pre-fold 180°.

》Segmental crash lock bottom device.

》Touch screen control plane.

》High speed eiectric kick board counter.

》Collectiog unit cylinder control pressure type pressure system.

》Remote control convenience for operators to remote control the start and stop of machine.

》Optional printing、 bar code and glue inspection unit.

Performance Specifications:

|

Model

|

JH650

|

JH850

|

JH1100

|

|

MAX.SHEET SIZE

|

650×700mm

|

850×900mm

|

1100×900mm

|

|

MIN.SHEET SIZE

|

120×70mm

|

125×70mm

|

130×70mm

|

|

APPLICABIE PAPER

|

Cardboard:250g-800g,corrugated paperF、E

|

|

MAX.BEIT SPEED

|

450M/min

|

450M/min

|

450M/min

|

|

MACHINE LENGTH

|

16043mm

|

16043mm

|

16043mm

|

|

MACHINEWIDTH

|

1350mm

|

1500mm

|

1800mm

|

|

MACHINE HEIGHT

|

1450mm

|

1450mm

|

1450mm

|

|

TOAI POWER

|

18.5KW

|

18.5KW

|

18.5KW

|

|

MAX.AIR DISPLACEMENT

|

0.7m3/min

|

0.7m3/min

|

0.7m3/min

|

|

TOTAL WEIGHT

|

5500kg

|

6000kg

|

6500kg

|

AC = Standard folding boxes , double-wall boxes and bottom lock boxes.

PC=Standard folding boxes , double-wall boxes and bottom lock boxes.

PCW=Standard folding boxes , double-wall boxes , bottom lock boxes and 4/6 corner boxes.

Specific auxiliaries can produce special boxes like CD boxes , ladder-shaped boxes , box-in-boxes , 3-fold silk stocking boxes.

This catalogue is for general reference only and special design is available.

Jinghong Packaging Machinery Co ., Ltd . reserves the final interpretation right of the above information.

Functional composition:

FEEDER

Independent motor driving systemSynchronized feeding with main motor

Equipped with vibrating sheet separation system.

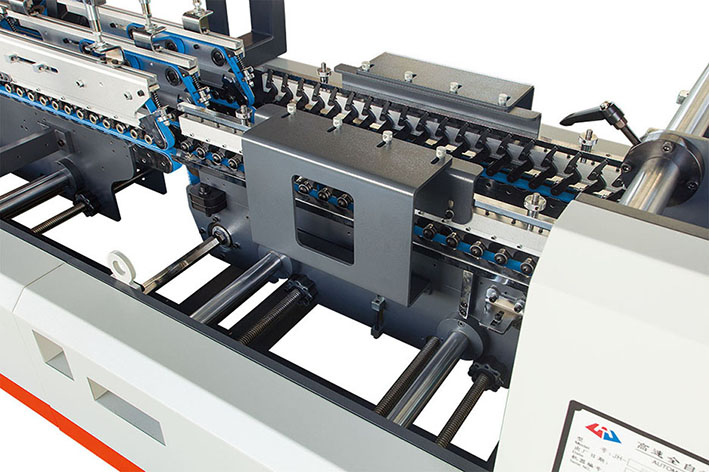

PAPER REGULATING DEVICE

Auto-correction of paper/sheets from the Feeder ensures feeding accuracy. Adjustable press drive fit for various thickness of paper/sheets.

PRE-FOLDING

Specific design ensures 180 degree on 1 st crease and165 degree on 3rd crease.

4/6 back-hook system can be added as upgrade (optional)

BOTTOM-FOLDING

Equipped with bottom lock combination/adjustment, with ideally flexible design that ensures fast and easy operation.

Sectional belt feeder with special design, fexible and adjustable per product requirerment without tightening or loosening the beit. Electronic giue sprayer(required)

FOLDING

2nd crease 180 degree,4th crease 180 degree Specifically designed to adjust belt feeding speed separately to correct box embryo running directior and ensure straight feeding.

TROMBONE(PRESSING)

Auto-collecting of paper/sheets and water spray by photoelectric counter.

Paper-jam inspection device

Adjustable upper and lower belts for easy and simple operation.

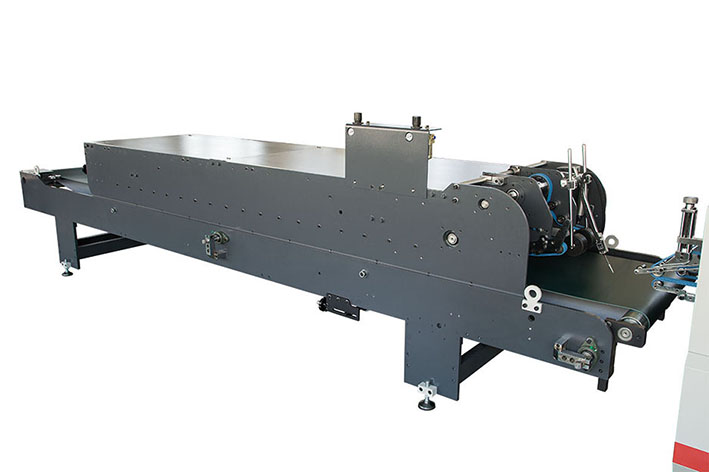

CONVEYOR

Movable stacking belts of 2 boards on left and right, adjustable on-line per stacking requirement to improve efficiency Extra sponge beit for pressing of concave part the box piles.

sireressedeeasy aoportronnwitn main notor in automatic mode to improve stable stacking.